Articles

Buying vs Hiring

Buying vs. Hiring Equipment for Your Business: Which Should You Choose?

When it comes to industrial safety and environmental monitoring, companies like EGM play a crucial role in providing essential equipment. However, many businesses often face a significant decision: should they buy or hire equipment? To answer this, you need to properly understand your company’s needs.

Cirrus Dosebadge

Introducing the Original doseBadge Noise Dosimeter

EGM is proud to present the Original doseBadge, the latest addition to our portfolio dealing with noise monitoring in the workplace. Through our close partnerships with leading brands like Cirrus, we understand how important reliable and accurate monitoring is to keep you compliant with health and safety legislation, and we’re confident that the new doseBadge stands out as a unique device for measuring occupational and industrial noise levels.

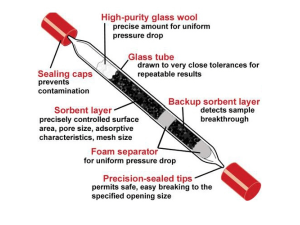

Air Sampling Equipment from EGM

Ensuring the safety and health of employees is paramount in any workplace and this often entails safeguarding against possible airborne dangers. Gases, vapours and particles of dust or from fibres can severely impact the lungs, kidneys and liver and can lead to serious illness.

EGM Pioneers the Latest Tech with Cirrus SoundSign

At EGM, we remain committed to sourcing the latest technology and making it available and easy-to-use for our customers. Our product range is continually expanding to empower them in making their workplaces safer and more efficient. The latest exciting addition to our expanding product range is the Cirrus Soundsign.

Fixed Gas Detection Installation - Case Study

Enhancing Gas Monitoring for Scottish Water: A Successful Partnership.

At EGM, we specialise in providing comprehensive environmental and gas monitoring solutions to a wide range of industries. We’ve been trusted suppliers of Crowcon gas detection products for over a decade and have enjoyed a successful partnership with Scottish Water for many years. This case study is a shining example of how well our collaboration works and it outlines how we addressed complex gas monitoring needs, ensured compliance and future-proofed their systems.

Hydrogen: A Promising Energy Source with Safety Prioritised

These days sustainability is top of everyone’s agenda, and the search for cleaner and more efficient energy is gathering pace. Electric vehicles are popular, but the public have concerns about their limited range, high costs and ethically questionable supply chains. However, there’s another contender in the energy revolution that is steadily emerging - hydrogen.

Hydrogen is a versatile gas that can be easily manufactured and used to not only power homes through an existing gas infrastructure, but also vehicles. In this blog, we’ll look at the growing potential of this easily produced gas, but also at crucial safety measures that are needed to unlock its obvious potential.

Intellidox Automatic Calibration and Bump Test Station

Revolutionize Your Gas Detector Management with IntelliDoX

To a business of any significant size, environmental safety is crucial and reliable gas detection is at the top of the list for protecting lives and the environment. As experienced industry leaders in environmental gas monitoring, EGM understands the importance of efficient instrument management, and that’s why we’re delighted to be able to offer IntelliDox, the latest automated instrument management system that has recently replaced the Microdock II.

New BW Flex portable gas monitor

The Honeywell BW Flex: a new standard of simplicity and reliability

At EGM, we continually aim to better serve our customers, and we’re delighted to announce the addition of the brand-new Honeywell BW Flex portable gas detector to our suite of available products.

Trojan Noise Nuisance Recorder

Noise can affect communities in a dramatic way. What may be just an irritating annoyance to some residents can do real damage to the relationships and wellbeing of other people living in close quarters with their neighbours.

The Trojan Noise Recording System is game-changing piece equipment designed in partnership with Local Councils, Environmental Health Officers and Housing Associations - the people who have a direct responsibility to manage this problem carefully, sensitively and efficiently.

Quantum Outdoor

Quantum Outdoor: EGM sets a new standard for integrated monitoring systems

The latest cloud-based solution

We’re delighted to announce that we’re now able to supply Quantum Outdoor: a brand-new cloud-based solution for remote noise-monitoring, unattended noise measurements - and lots more! This ground-breaking piece of equipment has been designed and developed by Cirrus Research and is unlike anything else on the market.